COMPOSITE MATERIALS

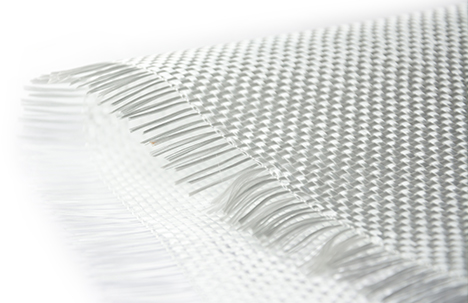

Asia Kangnam offers a wide range of Carbon, Glass, and Aramid Fibers which are woven to produce reinforcement materials for composite structures. Bi-directional fabrics comes in different weave patterns for strengthen at 0 and 90 degrees.

Uni-directional fabrics have reinforcement running only at 0 degree giving it greater strength at a fraction of the cost.

WEAVE STYLES

The ability of a woven fabric to conform to a complex surface (drapeability), surface smoothness and stability of a fabric are controlled primarily by the weave style.

|

PLAIN WEAVEThe plain weave creates the maximum amount of interlacing possible as each warp fibre passes alternately under and over each weft fiber. Therefore the fabric is symmetrical, having good stability, good impact resistance and reasonable porosity. |

|

TWILL WEAVEOne or more warp fibers alternately weave over and under two or more weft fibers in a regular repeated manner. The twill weave delivers the visual effect of a straight or broken diagonal “rib” to the fabric and reduces crimp. This contributes to a smoother surface and better wet out and drapeability over the plain weave with only a small reduction in stability. |

|

SATIN WEAVEThe Satin Weave is fundamentally the same as the plain weave except that two or more warp fibers alternately interlace with two or more weft fibers. This weave is flatter, and, through less crimp, stronger than a plain weave, but it is also less stable. It should be used on heavy weight fabricsmade with thicker (high tex) fibers to avoid excessive crimping. |

PRODUCT CUSTOMIZATION

Asia Kangnam is ready to go above and beyond to meet specific customer requirements whenever need be. We have the ability to tailor fabrics to meet the individual needs of our customers. Product parameters can be adjusted based on the final application in order to deliver the expected performance.

FABRIC WIDTHWoven fabric widths can be adjusted to the customer’s needs without off-cut. The most common widths for woven fabrics are comprised of 100cm, 127cm, and 150cm. Depending on the client’s preferences, the product width can range from 150 mm tapes up to 3800 mm for glass and from 970 to 1800 mmFiber Load for carbon fibre woven fabrics. In the case of tapes, for the better fixing of the edges melted yarn can be included. |

FIBER LOADFor applications requiring a high concentration of fibers and strength in only one direction, unbalanced woven fabrics can be produced using different fiber count and tex. Unidirectional woven fabrics can be produced with up to a 95/5 weight distribution between the warp and weft directions and are available in both warp (UD0°) and weft (UD90°) versions. |

SURFACE WEIGHTDepending on the fiber count and linear density, different areal weights per layer can be designed. E/ECR glass woven fabrics are available in total surface weights between 200 and 1500 g/m2. Carbon woven fabrics range from 200 to 800 g/m2. |

ROLL LENGTH/SIZEThe standard roll size is typically 30-50 kg for manual handling. The length of the rolls can be adopted based on the customer’s process needs. For continuous production processes, the product length can be adjusted to more than 1000 linear metres. |

FEATURE AND BENEFITS

|

Interlocked layers between the fibers help to prevent delamination |

|

Crimp engineered to deliver high impact resistance |

|

Cost-effective reinforcement to deliver lower finished part costs |

|

Regular porosity leads to fast wet-out and application |

|

Design flexibility due to different weave patterns |

|

Product widths can be adjusted to customer needs without off-cut |

Asia Kangnam is pleased to now offer first quality shorts and remnants of fiberglass material.